Sportswear is an unprecedented new fashion, deeply integrated into our daily commuting life. Whether it is sweating on the field, fierce confrontation posture, or the streets and alleys to lead the trend of wearing show, sportswear have won the majority of consumers a wide range of favor and deep love.

01 The ultimate in craftsmanship and materials

In sports events, the passion of the fans is not only focused on the players, but also poured into the team uniforms. Team uniforms created by top brands transcend the boundaries of clothing and become the “holy grail” in the hearts of fans, carrying admiration and love. Wearing the same model, fans seem to be transformed into warriors, and idol side by side to fight, share the passion and glory.

However, behind the same clothing of these teams lies the ultimate pursuit of craftsmanship and materials. Manufacturers who want to take orders from these brands must have profound professional strength and exquisite production skills. The cutting of fabrics for sportswear is one of the key tests of a manufacturer’s skills.

02 Innovation in cutting technology: “single layer cutting”

With the continuous innovation and upgrading of brand design, the cutting requirements for sportswear fabrics are increasing. Traditional cutting methods can no longer meet these high requirements, cutting inefficiency, untidy lines, affecting the overall aesthetics and comfort of the garment and other issues are endless. In this context, the “single-layer cutting” technology came into being and became the focus of many apparel manufacturers. Introduction of “single-layer cutting” technology: As the name suggests, “single-layer cutting” technology refers to the process of cutting only one layer of fabric at a time to ensure the accuracy of the cut and the smoothness of the lines. Revolutionary technology: This technology is a revolutionary breakthrough for garments such as basketball jerseys, soccer jerseys, and striped shirts/suits that require precise strip-to-grid cutting.

03 Faster digital cutting systems for small and irregular production runs

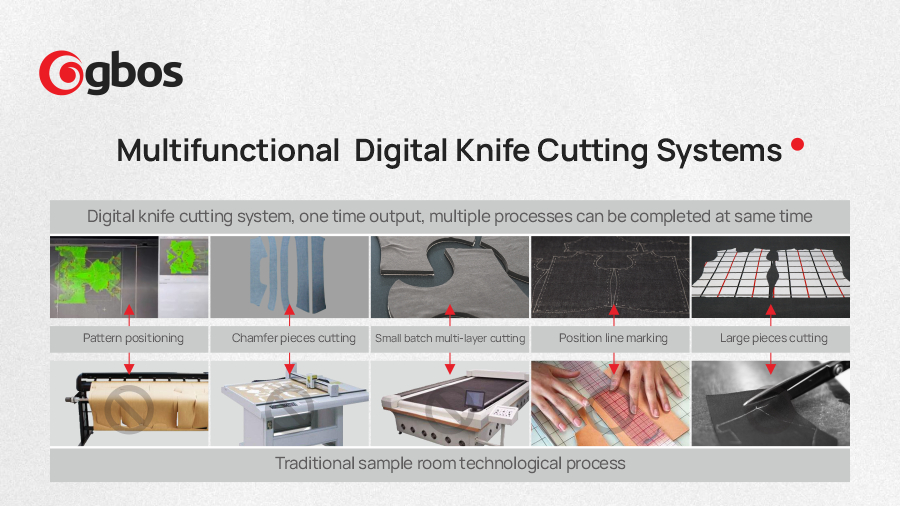

In response to this market demand, we proudly present the VC9-1820SSCCD Multi-functional Digital knife Cutting System.

Advanced Functions: This machine is not only equipped with an advanced AI visionscan system, which can accurately recognize various complex fabric patterns and textures, but also has been fully upgraded and optimized in terms of core functions and configuration.

Cutting ability: Whether it is the efficient multi-layer cutting of the vibrating knife cutting system or the high-speed and precise cutting of the single-layer cutting system, it can easily cope with a variety of difficult cutting tasks.

Flexibility and diversity: At the same time, the addition of the paintbrush device and O-shaped/V-shaped punching device adds more flexibility and diversity to this cutting machine, meeting the diverse cutting needs of users.

We believe that in the days to come, this solution will become the right-hand man and the winning weapon of many apparel manufacturers, and jointly promote the innovation and upgrading of the sportswear industry.

Let’s work together to meet a better future for sportswear! In this era full of challenges and opportunities, let’s write a brilliant chapter of sportswear industry with more enthusiasm and stronger faith!

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: