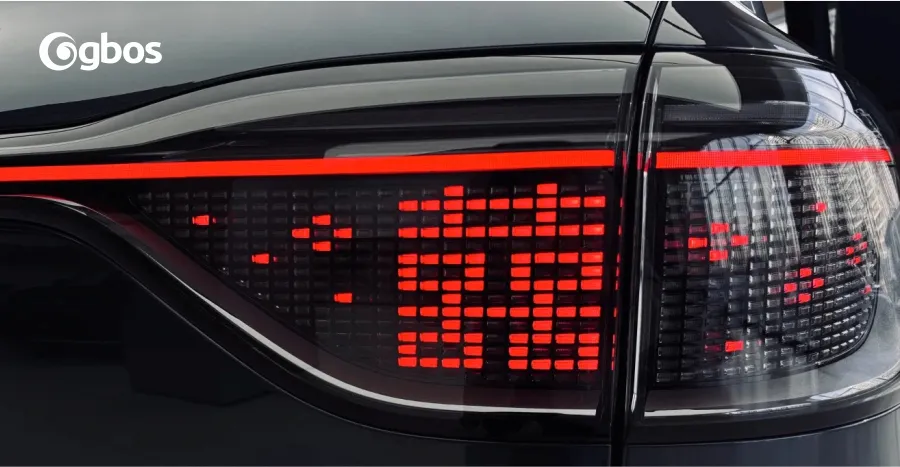

As the automotive industry thrives, new energy vehicles have emerged as a key force driving transformation. Consumers’ demands are no longer limited to basic transportation; expectations for aesthetics and technological experiences continue to rise.

01 Headlights: The Leap from “Bright” to “Smart”

Headlights, as a key element of automotive design and safety, have become increasingly important. Evolving from traditional lighting tools into core components that integrate aesthetics, technology, and interactive functions, this transformation drives automakers to continuously explore innovative headlight designs and processing techniques.

02 Challenges Faced by Automakers

02 Challenges Faced by Automakers

As headlight designs become more personalized and complex, automakers face numerous challenges in the manufacturing process. Unique lighting effects in new energy vehicles, such as seamless light strips and breathing interaction lights, demand precise cutting and fine craftsmanship. However, traditional processing methods struggle to handle the intricate shapes of 3D, curved, and irregular headlights.

In headlight gate cutting, traditional processes struggle to ensure smooth and precise edges, often requiring extensive manual grinding and finishing. This not only increases labor costs but also impacts production efficiency and the consistency of product quality.

When cutting at varying heights, the complexity of the cutting positions makes it difficult for traditional equipment to achieve precise positioning and cutting. This results in a high defect rate, severely limiting automakers’ production efficiency and slowing down product innovation.

03 The Master Craftsmen of Automotive Parts Processing

The GBOS GN602-3D 3D Five-Axis Precision Laser Cutter is specially designed to meet the complex processing needs of the automotive industry. It demonstrates exceptional performance in the cutting and trimming of automotive headlights, lamp covers, light strips, and both interior and exterior plastic parts.

Flexible Cutting: The equipment is equipped with a professional 3D five-axis cutting system, where the U-axis enables 360° infinite rotation, and the W-axis allows for ±180° oscillation.

Highly Customizable: Considering the differences in production scale and product specifications among automotive companies, the equipment offers impressive flexibility in size. Its maximum XYZ travel can reach 1800*1500*200mm and can be customized based on the customer’s specific needs. Whether for large-scale production of standard-sized parts or small-batch production of customized specifications, it perfectly adapts to provide personalized production solutions for businesses.

Efficient Replacement: In the automotive interior and exterior processing field, traditional methods such as stamping of automotive interior and exterior films and manual trimming are inefficient and produce inconsistent quality.

The equipment efficiently replaces these traditional processing methods, significantly shortening production cycles while ensuring stable product quality. This reduces production costs for businesses and enhances their market competitiveness.

04 Immersive Experience: A Must-Attend Event for Global Automotive Lighting Manufacturers

From March 26-28, 2025, at Booth T372 in Hall A of the Huqiao International Expo Center in Kunshan, Jiangsu, we will present a one-stop laser and automation application solution for the automotive industry. Particularly noteworthy is our star exhibit—the “3D Five-Axis Laser Cutter,” which will make its dazzling debut.

This equipment, combining cutting-edge technology and exquisite craftsmanship, not only demonstrates the ultimate precision and flexibility of laser cutting technology but also perfectly embodies the “precision craftsmanship” concept in the automotive lighting manufacturing field. If you are in the automotive lighting or automotive interior and exterior industry, we invite you to bring your materials and join us on-site for an in-depth exchange.

Car lights are not only the eyes of a vehicle but also a fusion of technology and art, ensuring both safety and aesthetics. On the journey of exploration and innovation, we understand that every step must be taken with solid footing, and every moment demands relentless pursuit of excellence.

Let us join hands and move forward, continuously exploring the unknown, challenging limits, and together writing a brilliant new chapter in the manufacturing of car lights and the entire automotive industry.

We will be waiting for you in Kunshan from March 26-28, 2025. Don’t miss it!

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: