In the gorgeous end of October, the 6th Automotive Seating Conference & Exhibition, an event focusing on the automotive seating industry, was grandly kicked off from 31st October to 1st November 2024 at Holiday Inn Express Pudong, Shanghai. The theme of this conference is ‘’Seat‘ Ride: Innovation and Sustainable Development Leads to the Ultimate Driving Experience’, which is elaborately planned by Ximai, attracting top talents and leading enterprises in the global automotive seating industry to gather together and explore the infinite possibilities of technological innovation and industry development. Infinite possibilities of technological innovation and industry development.

01 Intelligent Manufacturing: A New Engine for the Transformation and Upgrading of the Automotive Industry

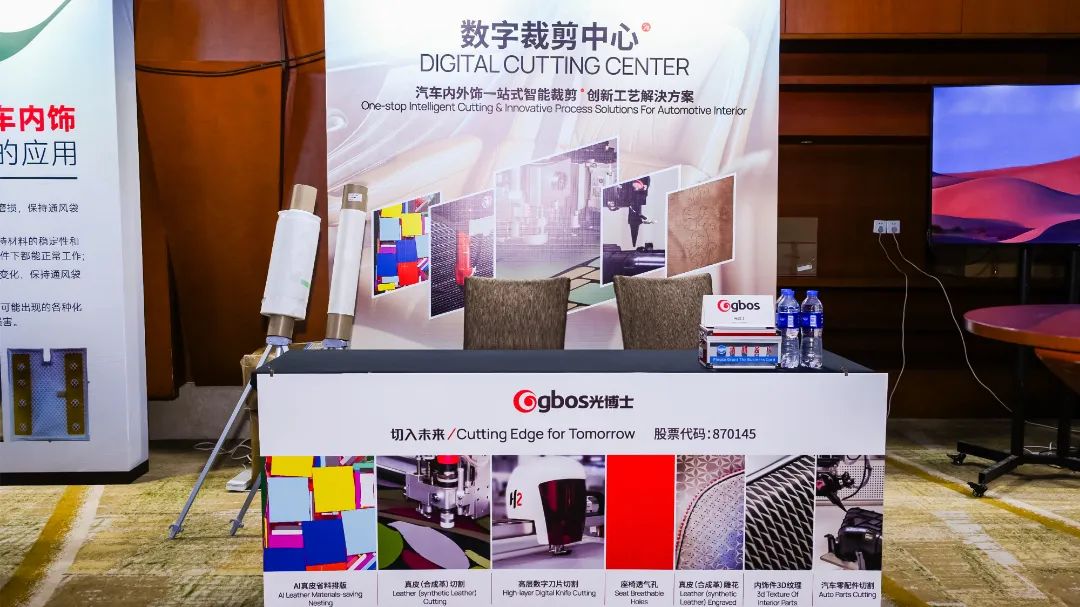

With the rapid changes in technology, intelligence and digitalisation have become an irreversible trend in the automotive industry. In this context, as a leader in the field of intelligent manufacturing, GBOS was invited to appear in this conference, bringing its forward-looking ‘one-stop intelligent cutting and innovative process solutions for automotive interior and exterior trim’. In the exhibition session, GBOS proudly introduced a number of advanced intelligent manufacturing equipment and technologies, including ITS5-3012 AI leather intelligent nesting system, KC3060TT×2 leather digital cutting system, XXP4-180 marking and cutting system, and GN641-2AT laser cutting system, etc. These innovative technologies and intelligent equipment are not only the best solution for automotive interior and exterior trims, but also the best solution for automotive interior and exterior trims. These innovative technologies and intelligent equipments not only significantly improve the production efficiency and reduce the production cost of automobile enterprises, but also provide a solid technical guarantee for the intelligent manufacturing of automobile interior and exterior trims, which strongly promotes the pace of intelligent transformation and upgrading of the automobile industry.

02 Meeting the Challenge: An Icebreaker for Manufacturers and Producers

Faced with an increasingly competitive market environment and increasingly diversified consumer demands, automobile manufacturers and producers are facing unprecedented challenges. How to improve production efficiency and reduce production costs while ensuring product quality has become a key issue constraining the development of the industry. At the same time, increasingly stringent environmental regulations also require automakers and producers to take the path of green production and reduce energy consumption. In response to these challenges, GBOS has proposed practical solutions. Through intelligent and digitalised production methods, he helps automakers and producers to crack the development problems and achieve the goal of efficient, green and sustainable development.

03 New Trend of Intelligent Manufacturing, Focused by Industry Experts

At the forum site of the conference, GBOS booth became the focus of attention. Numerous industry experts and scholars came to consult and communicate with each other, discussing the application prospect and development trend of intelligent manufacturing in the field of automobile manufacturing. GBOS professional team actively interacted with visitors, patiently answered questions, shared industry information and practical experience, and won wide praise and recognition. GBOS innovative achievements not only highlight its leading position in the field of intelligent manufacturing, but also point out the direction of the future development of the automotive industry.

04 Leading Intelligent Manufacturing and Creating a New Chapter in the Automotive Industry

The relevant person in charge of GBOS said, ‘In this exhibition, we not only show GBOS innovative achievements in the field of intelligent manufacturing, but also hope to promote the innovation and development of the automotive manufacturing industry through in-depth exchanges and co-operation with colleagues in the industry. In the future, GBOS will continue to increase its investment in the field of intelligent manufacturing, and is committed to researching and developing more cutting-edge technologies to provide more comprehensive and high-quality solutions for the automotive manufacturing industry.’ GBOS will join hands with industry partners to depict the bright future of automotive intelligent manufacturing, so that every driver and passenger can enjoy a safer, more comfortable and environmentally friendly driving experience.

In the surging wave of intelligent manufacturing, GBOS will, as always, play the role of a leader, leading the intelligent manufacturing of automotive interior and exterior decoration to climb new heights, pouring a steady stream of power into the flourishing development of the automotive industry and contributing to a more outstanding force.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: